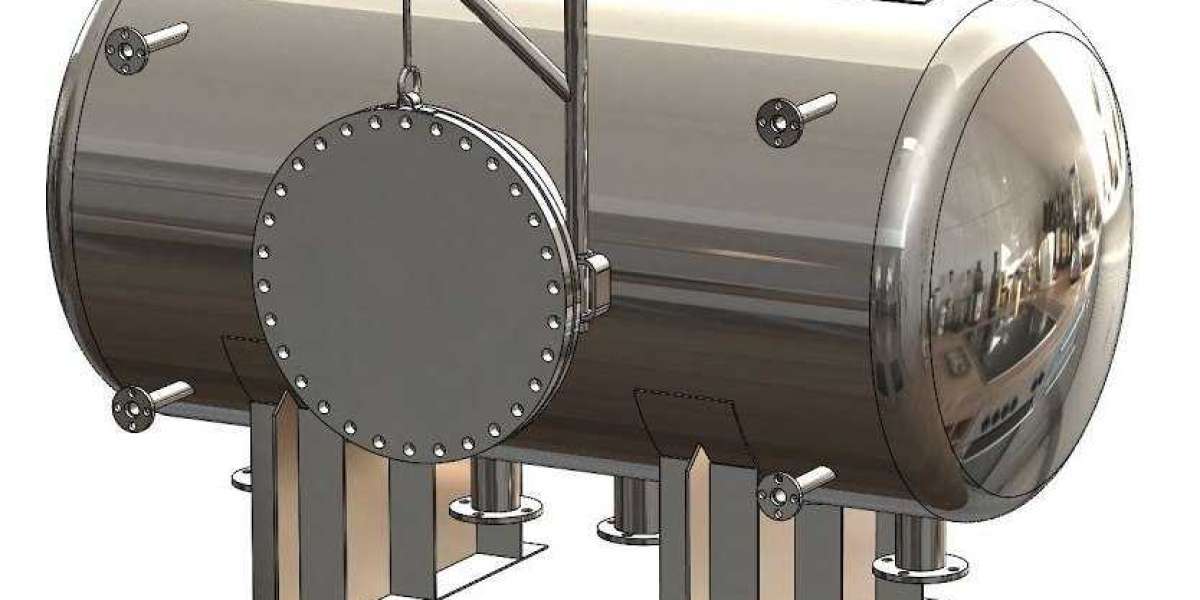

Stainless steel tanks can be fabricated with agitators, manways, and level gauges to meet specific requirements. They are also suitable for storage in a variety of environments and conditions.

Free From Corrosion

Stainless steel tanks are a popular choice for storage of liquids in environments where corrosion resistance is a priority. These tanks are often used in food production and manufacturing, and can hold everything from water to hazardous chemicals.

Unlike carbon steel, which has a tendency to corrode over time, stainless steel can resist deterioration thanks to its chromium content. This element forms an invisible film of metal oxides over the surface of the metal, which acts as a barrier against corrosion. The metal also has good thermal and electrical properties, making it suitable for a variety of applications.

In addition to its corrosion resistance, stainless steel has good strength and durability, making it an ideal material for transportation containers. These containers are commonly found on ships and road tankers, as well as in refuse vehicles. They are also popular for storing chemicals and liquids, because they are durable and have excellent leakage resistance. s/s tanks or surplus stainless steel tanks are the best to use. stainless steel tanks near me at surplus tanks. buy stainless steel tank at surplusrecord. used stainless steel tanks for sale are also at surplus stainless steel tanks. Moreover, stainless steel tanks are hygienic and easy to sterilize. They are often used in medical facilities to store products like ice water, milk, juices and ingredients. They are also commonly used in manufacturing procedures that require a high level of purity and cleanliness. In fact, stainless steel is so versatile that it can even be used in dental and medical equipment, such as cannulas, kidney dishes, and operating tables. Stainless steel is also used in many replacement joints, such as artificial hips.

It is easy to clean

Stainless steel tanks are durable, easy to clean, and undeniably hygienic. This makes them an excellent alternative to plastic or concrete storage containers, which can be prone to bacteria and mildew. Moreover, they are more cost-effective than other storage items that require frequent replacements. Whether you are storing water or other chemicals, a stainless steel tank is an excellent choice.

The best way to clean a stainless steel tank is by using cleaning solutions. There are many cleaning products on the market, but you should choose a cleaner that is compatible with the surface finish and material grade of your tank. Avoid abrasive cleaners as they may cause scratching. Also, make sure to use a non-metallic brush. Cleaning a stainless steel tank is a crucial step in the process of manufacturing, as it ensures that no contaminants will ruin the next batch. Unwanted bacteria or chemicals can destroy the next production batch, resulting in lost revenue and time. In addition, contaminated water can be harmful to humans and animals.

Stainless steel tanks can be cleaned with a solution of hot water and laundry detergent powder. You can also use an alkaline cleaner to remove organic residues from the surface. The concentration of the alkaline cleaner can be adjusted depending on the degree of contamination. Before applying the cleaning agent, it is important to pre-rinse the tank to prevent water erosion.

Stainless steel is a durable material

Stainless steel tanks are durable and have a long lifespan. They’re also easy to clean and do not harbor bacteria, making them hygienic. These properties make them a great choice for industries that require strict cleanliness standards, such as hospitals and kitchens. They’re also non-porous and can be used to store a variety of substances, including water, chemicals, pharmaceuticals, and food products.

Various alloying elements can be added to stainless steel to create different grades. The most common grades are 304/304L, 316/316L, and duplex stainless steel. These variations are based on the amount of corrosion-resistant chromium present in the metal. Stainless steel tanks can be custom-fabricated to meet the specific needs of each industry.

For example, a rancher may need a large storage tank to hold feed for their livestock. The right custom metal fabricator can fabricate a large storage tank with a hopper for easier feed dispersal. In addition, they can also add seismic anchoring to these tanks to ensure the tanks are safe during earthquakes.

Stainless steel is also eco-friendly and recyclable. In fact, over 50% of new stainless steel is recycled and remelted into fresh material. This reduces demand for raw materials and energy, which is good for the environment. This makes it a sustainable metal for both manufacturers and consumers. It’s also less expensive than other materials, such as concrete or plastic.

It is easy to maintain

Stainless steel tanks are able to store a wide variety of materials. They are also less prone to germs, mildew and leakage compared with plastic storage tanks. They can even be used in areas where there is corrosive water. Moreover, they are safe to use because of their non-reactive metal alloy composition and superior corrosion resistance. They can be easily cleaned with chemicals and require low maintenance.

The production of stainless steel tanks begins with the design phase, where engineers create detailed blueprints and specifications for the tank based on its intended use. Then, sheets of stainless steel are cut and shaped using shearing or laser cutting techniques to form the tank’s components. These parts include the base, lid, and agitator. In addition, stainless steel tanks have manways, which are openings in the tank that allow for access during maintenance, cleaning, and inspection. Stainless steel tanks can be installed in a variety of ways, including in open air and under the sun. The solar installation method is particularly useful for storing chlorine, as it assists in the water’s evaporation and reduces its odour. Moreover, it prevents bacterial growth and keeps the water fresh. Alternatively, a pump can be used to recirculate the chlorine water to prevent it from becoming stagnant.